Product Introduction

Product Introduction

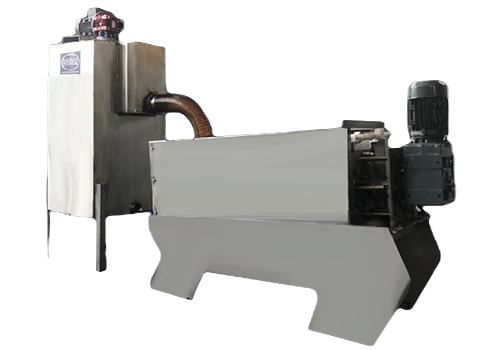

Multi Disk Screw Press

Dewatering of sludge with a moving shell screw press is one of the most modern and advanced techniques in the world.

The sludge enters the inner chamber of the screw and is compressed due to the rotation of the variable pitch screw, and the water separated from the shell is separated as filtrate. Due to the structure of the shell, which consists of triangular rings, it simultaneously prevents the pores of the shell from closing, and by increasing the pressure at the end of the screw due to the reduction of the pitch of the blades, the dewatering is done completely and the cake is discharged from the end part. be made

The advantages of the multi-disk screw press machine:

- Very low depreciation compared to other sludge dewatering equipment due to the low speed and pressure of the device

- The need for very little space compared to other sludge dewatering equipment

Reduction of energy consumption compared to centrifuge up to 20 times

- Low consumption of polyelectrolyte compared to equipment such as belt press, filter press and centrifuge (decanter) by at least 30%

- Easy operation and maintenance

- No need for permanent operator and easy management

Excellent compatibility with oily and greasy sludge

- Continuous work 24 hours a day, even when washing the device

- No need for thickening unit (thickener)

- Non-clogging due to continuous movement of discs

- No need for a filter or any consumable parts - The device is made entirely of 304 stainless steel and has a high resistance to corrosion.

- The device does not make any noise or vibration due to its low speed operation.

Application:

Textile industries, paper and cardboard manufacturing, food industries, chemical industries, metal industries

Refinery, petrochemical, livestock and poultry, slaughterhouses of animal breeding centers

Plating industries, tanning industries, cosmetics industries, pharmaceutical industries

and other industries that somehow produce sludge in the process of product production or wastewater treatment.